Hip Implants

Total hip joint replacement (THR) is an orthopaedic success story, enabling hundreds of thousands of people to live fuller, more active lives. Using metal alloys, high-grade plastics and polymeric materials, orthopaedic surgeons can replace a painful, dysfunctional joint with a highly functional, long-lasting prosthesis. Over the past half-century, there have been many advances in the design, construction and implantation of artificial hip joints, resulting in a high percentage of successful long-term outcomes.

Implant design

The hip joint is called a ball-and-socket joint because the spherical head of the thighbone (femur) moves inside the cup-shaped hollow socket (acetabulum) of the pelvis. To duplicate this action, a total hip replacement implant has three parts: the stem, which fits into the femur and provides stability; the ball, which replaces the spherical head of the femur and the cup, which replaces the worn-out hip socket. Each part comes in various sizes in order to accommodate various body sizes and types. In some designs, the stem and ball are one piece; other designs are modular, allowing for additional customization in fit. Several manufacturers make hip implants. The brand used in your case depends on many factors, including your needs (based on your age, weight, bone quality, activity level and health), the surgeon’s experience and familiarity with the device, and the cost and performance record of the implant. These are issues you may wish to discuss with your surgeon.

Many people credit Sir John Charnley with performing the first modern total hip replacement. His innovations included combining a metal stem and ball with a plastic shell and using a methacrylate cement, similar to the cement used by your dentist, to hold the devices in place.

Today, the stem portions of most hip implants are made of titanium- or cobalt/chromium-based alloys; they come in different shapes and degrees of roughness. Cobalt/chromium-based alloys or ceramic materials (aluminum oxide or zirconium oxide) are used in making the ball portions, which are polished smooth to allow easy rotation within the prosthetic socket. The acetabular socket can be made of metal, ultrahigh molecular weight polyethylene, or a combination of polyethylene backed by metal. All together, these components weigh between 14 and 18 ounces, depending on the size needed.

All the materials used in a total hip replacement have four characteristics in common:

* They are biocompatible; that is, they can function in the body without creating either a local or a systemic rejection response.

* They are resistant to corrosion, degradation and wear, so they will retain their strength and shape for a long time. Resistance to wear is particularly significant in maintaining proper joint function and preventing the further destruction of bone due to particulate debris generated as the implant parts move against each other.

* They have mechanical properties that duplicate the structures they are intended to replace; for example, they are strong enough to take weightbearing loads, flexible enough to bear stress without breaking and able to move smoothly against each other as required.

* They meet the highest standards of fabrication and quality control at a reasonable cost.

During a THR, the surgeon will take a number of measurements to ensure proper prosthesis selection, limb length and hip rotation. After making the incision, the surgeon works between the large hip muscles to gain access to the joint. The femur is pushed out of the socket, exposing the joint cavity. The deteriorated femoral head is removed and the acetabulum is prepared by cleaning and enlarging with circular reamers of gradually increasing size. The new acetabular shell is implanted securely within the prepared hemispherical socket. The plastic inner portion of the implant is placed within the metal shell and fixed into place.

Next, the femur is prepared to receive the stem. The hollow center portion of the bone is cleaned and enlarged, creating a cavity that matches the shape of the implant stem. The top end of the femur is planed and smoothed so the stem can be inserted flush with the bone surface. If the ball is a separate piece, the proper size is selected and attached. Finally, the ball is seated within the cup so the joint is properly aligned and the incision is closed.

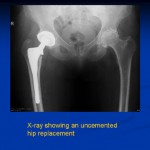

Hip replacements may be “cemented,” “cementless” or “hybrid,” depending on the type of fixation used to hold the implant in place. Although there are certain general guidelines, each case is individual and your surgeon will evaluate your situation carefully before making any decisions. Do not hesitate to ask what type of implant will be used in your situation and why that choice is appropriate for you.

Cemented THR

Cemented THR

Over the past 40 years, there have been many improvements in both the materials and the methods used to hold the femoral and acetabular components in place. Today, the most commonly used bone cement is an acrylic polymer called polymethylmethacrylate (PMMA). A patient with a cemented total hip replacement can put full weight on the limb and walk without support almost immediately after surgery, resulting in a faster rehabilitation. Although cemented implants have a long and distinguished track record of success, they are not ideal for everyone.

Cemented fixation relies on a stable interface between the prosthesis and the cement and a solid mechanical bond between the cement and the bone. Today’s metal alloy stems rarely break but they can occasionally loosen. Two processes, one mechanical and one biological, can contribute to loosening.

1. In the femoral component, cracks (fatigue fractures) in the cement that occur over time can cause the prosthetic stem to loosen and become unstable. This is more often the case with patients who are very active or very heavy. The action of the metal ball against the polyethylene cup of the acetabular component creates polyethylene wear debris. The cement or polyethylene debris particles generated can then trigger a biologic response that further contributes to loosening of the implant and sometime to loss of bone around the implant.

2. The microscopic debris particles are absorbed by cells around the joint and initiate an inflammatory response from the body, which tries to remove them. This inflammatory response can also cause cells to remove bits of bone around the implant, a condition called osteolysis. As the bone weakens, the instability increases. Bone loss can occur around both the acetabulum and the femur, progressing from the edges of the implant.

Despite these recognized failure mechanisms, the bond between cement and bone is generally very durable and reliable. Cemented THR is more commonly recommended for patients over age 60, for patients with conditions such as rheumatoid arthritis and for younger patients with compromised health or poor bone quality and density. These patients are less likely to put stresses on the cement that could lead to fatigue fractures.

In the 1980s, new implant designs were introduced to attach directly to bone without the use of cement. In general, these designs are larger and longer than those used with cement. They also have a surface topography that is conducive to attracting new bone growth. Most are textured or have a surface coating around much of the implant so that the new bone actually grows into the surface of the implant.

The surgeon must be very precise in preparing the femur for a cementless implant. The implant channel must match the shape of the implant itself very closely. New bone growth cannot bridge gaps larger than 1mm to 2 mm. Cementless femoral components tend to be much larger at the top, with more of a wedge-shape. This design enables the strong surface (cortex) of the bone and the dense, hard spongy (cancellous) bone just below it to provide support. The acetabular component of a cementless THR also has a coated or textured surface to encourage bone growth into the surface. Depending on the design, these components may also use screws through the cup or spikes, pegs, or fins around the rim to help hold the implant in place until the new bone forms. Usually these components have a metal outer shell and a polyethylene liner. The pelvis is prepared for a cementless acetabular component using a process similar to those employed in a cemented procedure. The intimate contact between the component and bone is crucial to permit bone ingrowth.

Initially, it was hoped that cementless THR would eliminate the problem of bone resorption or stem loosening caused by cement failure. Although certain cementless stem designs have excellent long-term outcomes, cementless stems can loosen if a strong bond between bone and stem is not achieved. Patients with large cementless stems may also experience a higher incidence of mild thigh pain. Likewise, polyethelene wear, particulate debris, and the resulting osteolysis remain problems in both cemented and uncemented designs. Improvements in the wear characteristics of newer polyethylene and the advent of hard bearings (metal-on-metal or ceramic) may help resolve some of these problems in the future.

Although some surgeons are now using cementless devices for all patients, cementless THR is most often recommended for younger (under 50 years of age), more active patients and patients with good bone quality where bone ingrowth into the components can be predictably achieved. . Individuals with juvenile inflammatory arthritis may also be candidates, even though the disease may restrict their activities.

A hybrid THR has one component, usually the acetabular socket, inserted without cement, and the other component, usually the femoral stem, inserted with cement. This technique was introduced in the early 1980s, so long-term results are just now being measured. A hybrid hip takes advantage of the excellent track records of cementless hip sockets and cemented stems.

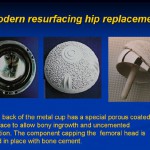

Hip resurfacing is a technique whereby more bone of the hip is preserved. The femoral neck is not cut as in a standard THR, but rather the head is re-shaped to accept a metal ball component that is fixed in place usually with cement. On the socket side, the cup is prepared to receive a thin metal shell to re-line the acetabulum. This design is not new, in fact some of the earliest hip replacements were resurfacing-type replacements but because of problems with manufacturing and the types of materials used they did not tend to last very long. Over the last 15 years there has been a resurgence of interest in resurfacing following the development of a successful implant by McMinn in Birmingham. It tends to be used for patients less than 60 with good bone and high activity levels. It can’t be used where there is much bone deformity or destruction.

The metal on metal bearing surface in hip resurfacing is also responsible for producing raised levels of cobalt and chromium in the blood and other organs. There have been reports in the recent literature of soft tissue and muscle damage occurring in relation to the metal ions released from the metal-on-metal articulation. This problem has mainly been associated with particular resurfacing prostheses, but concerns regarding these reactions has resulted in resurfacing being reserved for more selected cases.

Ceramic as a material has been used in hip replacements for many years. The attraction is that the wear rate is so low that this material gives a hip replacement the chance to last for many decades. A further advantage is that it is a very biocompatible material so that any wear particles that are released tend not to cause and adverse reaction in the tissues. Historically there have been some problems with ceramic implants breaking, but newer ceramic manufacturing techniques seem to have solved this problem. There have been reports of ceramic-on-ceramic articulations squeaking; this has usually been associated with particular implant types. On balance, many would feel that this type of articulation is most advantageous in younger patients, give the implant the best chance to last a long time.

Hip replacement operations are highly successful in relieving pain and restoring movement. However, the ongoing problems with wear and particulate debris may eventually necessitate further surgery, including replacing the prosthesis (revision surgery).Younger patients have a higher risk of failure. The chance of a hip replacement lasting 20 years is about 80 percent.